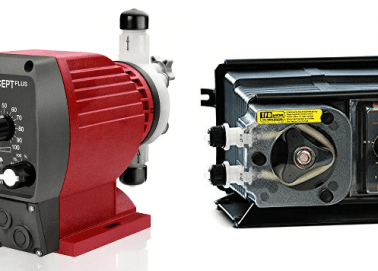

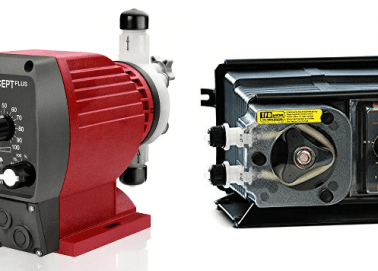

Head to Head – Chemical Dosing Pumps

March 1, 2019

Positive displacement chemical dosing pumps are a piece of equipment you’ll find as part of almost every pool mechanical system. Hypochlorite, pH adjustment chemicals & filter coagulants are all commonly dosed with one of two types of pump. Both diaphragm & peristaltic pumps have been long established as reliable and effective choices in the pool world. Within each type, there is a wide spectrum of performance factors depending on the brand and model of pump. It would be incorrect to say one type is superior, there are features unique to each that may make one type a better choice for your application. Here are some of the main feature differences:

Diaphragm Pump – Pros

- A lower cost of ownership is a general perk that can be claimed for diaphragm pumps- assuming the pump is correct for the application (size & material compatibility).

- It’s not uncommon to run 1-2 years without having to replace parts. Depending on the chemical – simple annual cleaning can be effective for maintenance.

- Have the potential to pump against very high line pressure (150-250 PSI is common but generally unnecessary for pool applications).

- Compatible with automatic ‘flush’ systems for insoluble slurry applications (4-5% soda ash).

- More readily compatible with ‘pulse’ control outputs for true proportional dosing control.

- Fractional amperage draw means less load on pump drive and external relays. Controller relay failures are almost always on a peristaltic pump.

Diaphragm Pump – Cons

- Particulate can cause issues with suction check valve seals and loss of prime issues.

- If an incomparable pump head is used – trapped gas vapours from sodium hypochlorite can air lock the pump head. Auto degassing heads are available for this application but are often overlooked.

- Lower stroke lengths (<50%) can lead to loss of prime during periods of low use.

- Requires more skill/knowledge to troubleshoot.

Peristaltic Pump – Pros

- Easy to prime as long as roller/tube are in good condition so they generally ‘self-prime’.

- Handles off-gassing and immune to air locks that can cause problems when sodium hypochlorite is dosed on diaphragm pumps without a de-gassing liquid end.

- Service & troubleshooting is simpler.

Peristaltic Pump – Cons

- Higher motor amperage load means the motor won’t last as long as on a diaphragm pump. This also adds extra load/stress on chemical controller relays.

- More frequent maintenance (tubes are generally good for 500 hours).

- Some models are limited to 25 PSI output.

- Tube failure can result in a dangerous chemical spill.

Positive displacement chemical dosing pumps are a piece of equipment you’ll find as part of almost every pool mechanical system. Hypochlorite, pH adjustment chemicals & filter coagulants are all commonly dosed with one of two types of pump. Both diaphragm & peristaltic pumps have been long established as reliable and effective choices in the pool world. Within each type, there is a wide spectrum of performance factors depending on the brand and model of pump. It would be incorrect to say one type is superior, there are features unique to each that may make one type a better choice for your application. Here are some of the main feature differences:

Diaphragm Pump – Pros

- A lower cost of ownership is a general perk that can be claimed for diaphragm pumps- assuming the pump is correct for the application (size & material compatibility).

- It’s not uncommon to run 1-2 years without having to replace parts. Depending on the chemical – simple annual cleaning can be effective for maintenance.

- Have the potential to pump against very high line pressure (150-250 PSI is common but generally unnecessary for pool applications).

- Compatible with automatic ‘flush’ systems for insoluble slurry applications (4-5% soda ash).

- More readily compatible with ‘pulse’ control outputs for true proportional dosing control.

- Fractional amperage draw means less load on pump drive and external relays. Controller relay failures are almost always on a peristaltic pump.

Diaphragm Pump – Cons

- Particulate can cause issues with suction check valve seals and loss of prime issues.

- If an incomparable pump head is used – trapped gas vapours from sodium hypochlorite can air lock the pump head. Auto degassing heads are available for this application but are often overlooked.

- Lower stroke lengths (<50%) can lead to loss of prime during periods of low use.

- Requires more skill/knowledge to troubleshoot.

Peristaltic Pump – Pros

- Easy to prime as long as roller/tube are in good condition so they generally ‘self-prime’.

- Handles off-gassing and immune to air locks that can cause problems when sodium hypochlorite is dosed on diaphragm pumps without a de-gassing liquid end.

- Service & troubleshooting is simpler.

Peristaltic Pump – Cons

- Higher motor amperage load means the motor won’t last as long as on a diaphragm pump. This also adds extra load/stress on chemical controller relays.

- More frequent maintenance (tubes are generally good for 500 hours).

- Some models are limited to 25 PSI output.

- Tube failure can result in a dangerous chemical spill.